Why the Spiral Ducting Machine Has Become Essential for Modern HVAC Projects

Nov 17, 2025

In recent years, the demand for high-efficiency ventilation systems has grown rapidly across commercial, industrial, and infrastructure projects. As energy-saving standards rise globally, spiral air ducts have become the preferred choice due to their airtightness, durability, and lower installation cost. This trend has made the Spiral Ducting Machine for Making Spiral Duct one of the most important pieces of equipment in the HVAC fabrication industry.

What Is a Spiral Ducting Machine?

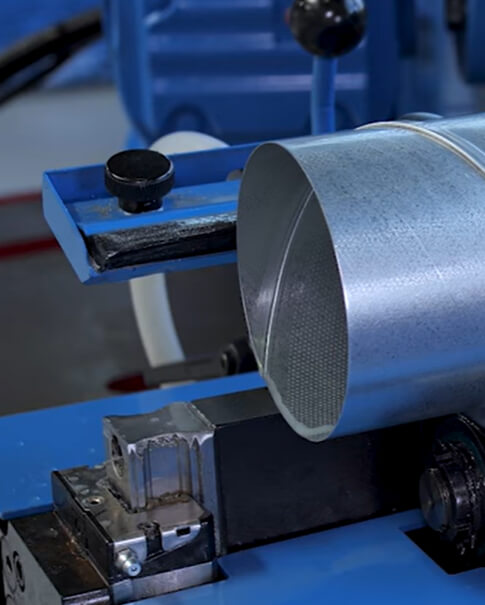

A Spiral Ducting Machine is specialized equipment designed to form continuous spiral ducts using galvanized steel, stainless steel, or aluminum. The machine winds metal strips into a spiral shape and locks the seams firmly, producing ducts with:

High structural strength

Excellent air tightness

Smooth interior surface

Long service life

These characteristics make spiral ducts widely used in HVAC, ventilation, industrial dust removal, tunnel ventilation, and more.

Who Needs a Spiral Ducting Machine?

The Spiral Ducting Machine is essential for companies that require high-volume, high-precision, and cost-efficient duct manufacturing, including:

1. HVAC System Manufacturers

Companies producing air conditioning and ventilation systems for commercial buildings, factories, hospitals, and airports rely on spiral ducts due to their stability and energy efficiency.

2. Sheet Metal Fabrication Workshops

Workshops aiming to expand production capacity or improve product consistency need automated duct machines to stay competitive.

3. Construction & Engineering Contractors

Contractors working on large ventilation projects benefit from producing ducts in-house to reduce project procurement costs and accelerate construction timelines.

4. Industrial Ventilation & Dust Removal System Providers

Spiral ducts are widely used in dust collection, industrial exhaust, and environmental protection equipment.

5. Global Exporters & OEM Suppliers

Manufacturers supplying ducts to overseas markets require machines that can meet standards such as SMACNA, DW144, and other international specifications.

Why Spiral Ducting Machines Are in High Demand Right Now

▶ Growth of Commercial Construction Projects

Shopping malls, hospitals, airports, and office towers increasingly adopt spiral ducts for central air conditioning systems.

▶ Global Push for Lower Energy Consumption

Spiral ducts reduce air leakage, improving overall HVAC efficiency.

▶ Rise of Prefabricated & Modular Construction

Fast installation and standardized components make spiral ducts ideal for modular building projects.

▶ Replacement of Traditional Square Ducts

More contractors are switching from rectangular ducts to spiral ducts because they require fewer accessories, reduce installation time, and offer lower long-term maintenance.

Key Advantages of a High-Quality Spiral Ducting Machine

A professional Spiral Ducting Machine delivers measurable benefits:

1. High Production Efficiency

Continuous duct forming meets the needs of large-scale HVAC projects.

2. Consistent Quality

Automatic forming ensures uniform diameter and stable seam locking.

3. Wide Size Range

Capable of producing duct diameters from small ventilation pipes to large industrial ducts.

4. Lower Material Waste

The machine’s precision and automated cutting reduce unnecessary scrap.

5. Long-term Cost Reduction

Significant savings in labor, time, and installation accessories.

Applications of Spiral Ducts Made by This Machine

Commercial HVAC systems

Industrial ventilation and exhaust

Subway and tunnel ventilation

Factory dust collection systems

Clean room and hospital air supply

Warehouse and logistics center ventilation

Airport and station central air ducting

Wherever clean, efficient, and reliable airflow is required, spiral ducts are a perfect fit.

Conclusion

The Spiral Ducting Machine for Making Spiral Duct has become a crucial investment for HVAC manufacturers and sheet-metal workshops. With the global shift toward high-efficiency ventilation, spiral ducts are no longer an option—they are a standard. Choosing a high-performance machine ensures stable quality, higher output, and long-term competitiveness.