What machine is needed to make a round ventilation duct?

Jul 29, 2024

Making round ventilation ducts requires a series of professional machine, which play a key role in material processing, forming, welding and surface treatment. Here are the main pieces of machine needed to make round ventilation ducts:

1.Spiral duct machine is a machine that produces spiral ducts. Spiral ducts, also known as spiral seam thin-walled tubes, form spiral ducts through continuous winding and welding. They are widely used in many fields and places.

For a detailed introduction, please view the spiral duct machine blog introduction.

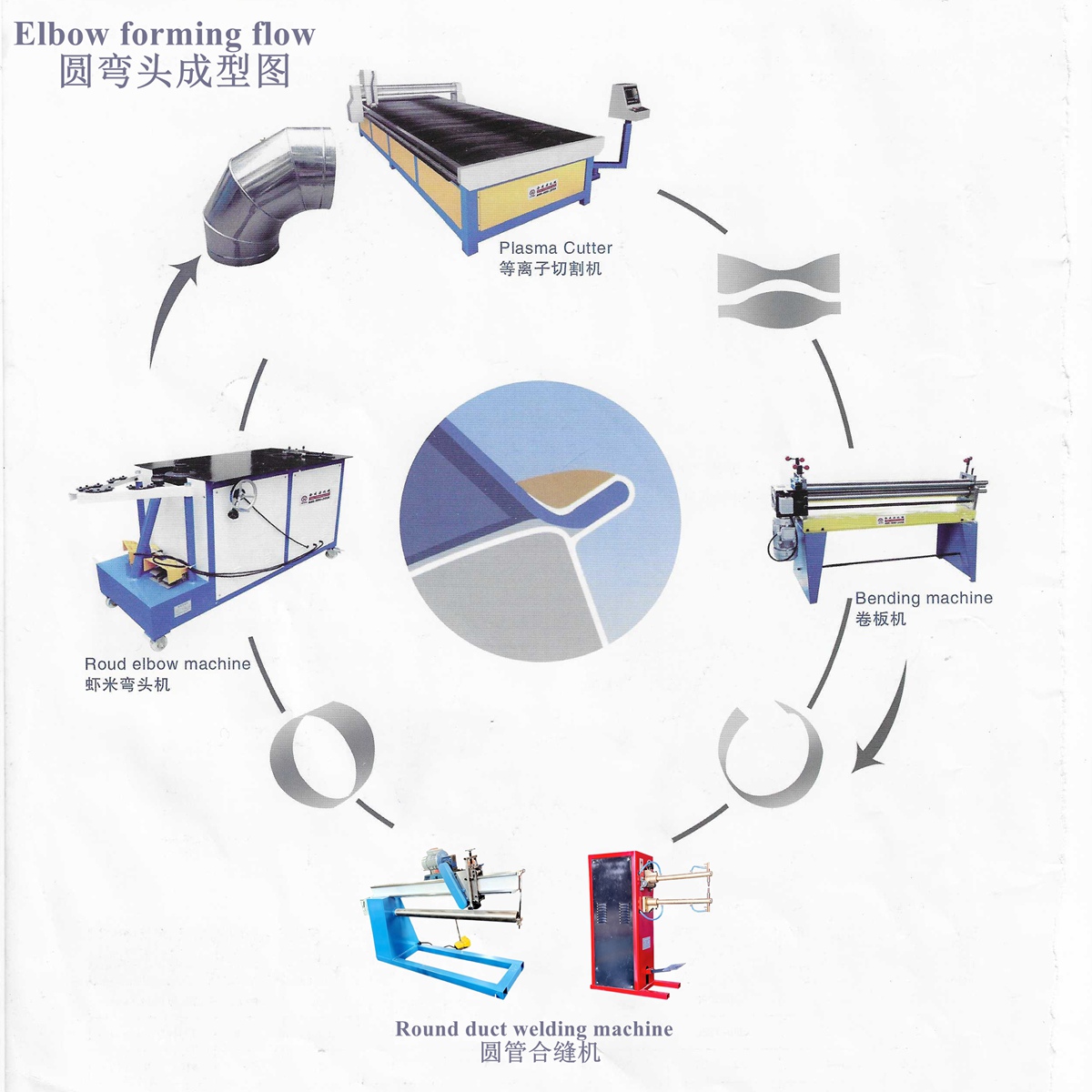

2.CNC Plasma cutting machine is a processing method that uses the heat of high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece, and uses the momentum of high-speed plasma to remove the molten metal to form the incision.

Also,for a detailed introduction, please view the CNC Plasma cutting machine blog introduction.

3.Electric rolling machine: used to roll the stamped plate into a cylindrical shape to form the main part of the air duct. The selection and use of the plate rolling machine has an important impact on the roundness and diameter accuracy of the air duct.

4.Round duct welding machine used to weld together stamped and rolled plates to form a complete air duct structure. Depending on the material, different types of welding machines may be required, such as argon arc welding machines, stainless steel welding machines, etc.

5.Elbow Making Machine, also known as round pipe elbow Making machine, is a special machine for processing metal sheet circular pipes and round pipe elbows (elbow bend) butt jointing.

6.Electric shearing machine: Uses a press to cut metal plates. It is one of the indispensable machine in the process of making round ventilation ducts. The electric shearing machine has the characteristics of fast cutting speed and high precision, and can meet the cutting needs of metal plates of different specifications and thicknesses.

7.Folding machine: Used to bend metal plates into the required shape. The folding machine can ensure that the corners of the air ducts are flat and have good sealing properties.

8.Rotary Beading Machine is a piece of machine widely used in the metal processing industry. It is mainly used for processing operations such as beading, threading, and flanging of metal sheets or pipes.

9.Horizontal Flanging Forming Machine is a piece of machine specially used to process metal sheets. It uses a specific process to process the sheet into a shape with curved edges, thereby enhancing the fixing and installation performance of the sheet.

10.Steel Angle Rolling Machine is a mechanical equipment specially used to bend angle iron and other profiles into round or arc shapes. This equipment is widely used in construction, metal processing, manufacturing and other fields.

11.Angle Steel Flange Production Line is a mechanical equipment production line specially used for processing angle steel flanges. It has the characteristics of high efficiency, precision and high degree of automation.

It should be noted that the above-mentioned machines are not all machines for making round ventilation ducts. The machine needs to be specifically selected based on production scale, product specifications, production technology and other factors. At the same time, when using these machines, operating procedures and safety must be strictly observed to ensure safety and stability during the production process.