Introduction to Steel Angle Rolling Machine

Sep 23, 2024

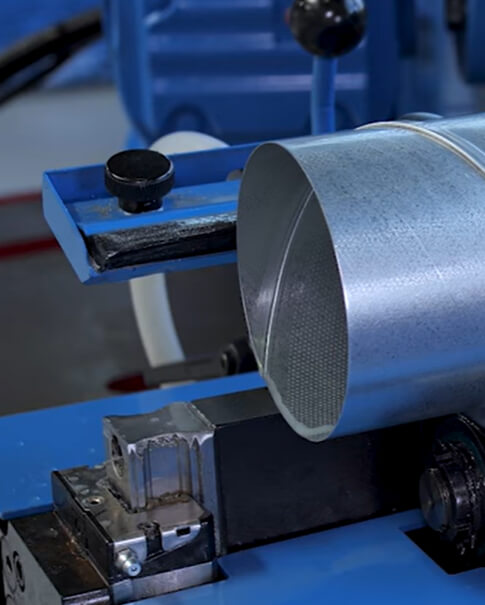

Steel Angle Rolling Machine is a mechanical equipment used to roll carbon steel, stainless steel, and non-ferrous metal profiles (such as angle steel, strip steel, channel steel, pipes, etc.) into rings and flanges. The following is a detailed introduction to the diagonal Steel Angle Rolling Machine:

1.Main functions and features

(1)Efficient rolling: It can quickly and accurately roll the profile into a ring or flange with the required diameter, improving production efficiency.

(2)Wide applicability: Suitable for various models and specifications of profiles to meet different engineering needs.

(3)Easy operation: equipped with advanced control system, making operation easier and faster.

Safe and reliable: Made of high-quality materials and advanced technology to ensure the stability and safety of the equipment during operation.

2.Main components

(1)Frame: Provides a solid support frame to ensure the stability and rigidity of the machine.

(2)Hydraulic system: It consists of oil pump, oil tank, solenoid valve and hydraulic cylinder, etc. It provides the required pressure and force to drive the bending and rounding process.

(3)Bending mold: used for fixing and bending angle iron, and can be adjusted according to different types of angle iron.

(4)Control system: By controlling the work of the hydraulic system, including controlling parameters such as pressure, speed, and bending angle, the precise bending and rounding of diagonal iron can be achieved.

3.Working principle

The working principle of the Steel Angle Rolling Machine is mainly to provide power through the hydraulic system to drive the bending mold to bend and round the angle iron placed on the mold. The operator first checks whether all components of the equipment are intact and adjusts parameters such as pressure and speed of the hydraulic system. Then, place the angle iron to be bent on the mold, start the hydraulic system, and make the mold bend and round the angle iron. During the bending process, the operator needs to pay close attention to the working status of the machine to ensure that the bent and rounded angle iron meets the requirements.

4.Application areas

Steel Angle Rolling Machine are widely used in construction, bridges, tunnels, subways and other engineering fields, as well as in steel structure processing, pipe manufacturing and other industries. It can effectively improve the processing efficiency and quality of profiles, and reduce production costs and labor intensity.

5.Operation precautions

(1)Before operation, check whether all components of the equipment are intact, and adjust parameters such as pressure and speed of the hydraulic system.

(2)During operation, it is necessary to pay close attention to the working status of the machine to ensure that the bent and rounded angle iron meets the requirements.

(3)After the operation is completed, the machine needs to be shut down and maintained in time to extend the service life of the equipment.

6.Market Price and Brand

The market price of Steel Angle Rolling Machines varies depending on factors such as brand, model, specification, etc. There are many well-known brands and models on the market to choose from, such as Honghao, Wanze Jinda, Minghui Heavy Industry, etc. For specific prices, please consult the relevant manufacturers or dealers for the latest information.

To sum up, the Steel Angle Rolling Machine is an efficient and practical profile processing equipment that plays an important role in construction, bridges, tunnels and other engineering fields. During the selection and use process, comprehensive consideration and selection must be made based on actual needs.